CNC machining stands for Computer Numerical Control machining. We are surrounded by products of CNC machining in our everyday lives. With decades of advancements, adjustments, and successes in the manufacturing industry, CNC machines have increased in their capacity. These machines can adapt to a variety of shape, size, and material requirements to bring to life the most intricate blueprints for functional and non-functional products. From pens to violins to aircraft engines, the possibilities of products fabricated through CNC machining are endless.

Different Types of CNC Machining:

The following list contains examples of CNC Machining capabilities used by Accuturn:

3/4/5-Axis CNC Milling: CNC Milling is a complex specialty in the world of precision machining. CNC Milling is a manufacturing process where a programmed machine directs rotating cutting tools to remove intricate pieces from an existing material on a 3-axis, 4-axis, or 5-axis plane. Depending on the CNC Milling Center, the rotational movement applies to the cutting tools, tabletop, or both. This process is helpful in creating highly-detailed, precise, and complex components all at a higher production rate.

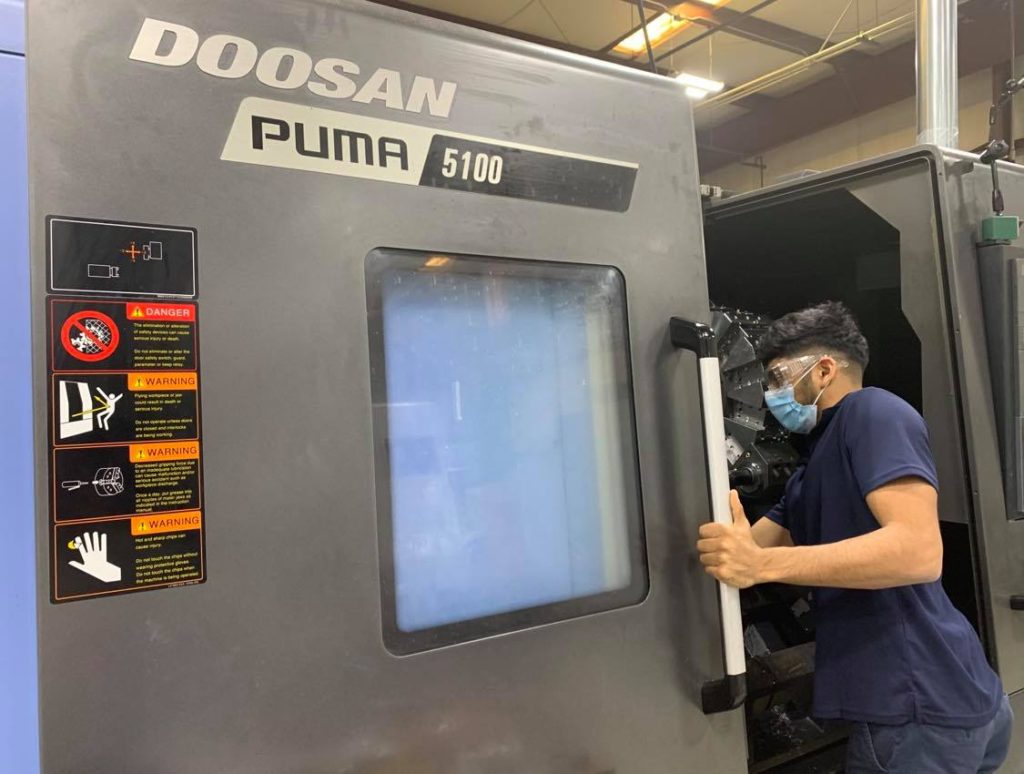

CNC Turning: CNC Turning is a manufacturing process in which material is removed from an existing metal bar, rod, or slug on either a vertical or horizontal axis. Within a CNC Turning machine, the material is held by a chuck/jaws and rotated as a tool removes metal from its body. This computer-numerical controlled program then directs the machine as necessary in order to fabricate the component. CNC Turning allows for products to maintain high accuracy and tight tolerances to meet assembly specifications.

CNC Swiss Screw Machining: CNC Swiss Screw Machining is a computer numerical controlled manufacturing processes that utilizes programmed codes to simultaneously direct tools and material to create the desired component. This material-removal technology creates small, detailed, and threaded screw components for customers to use in their assemblies. Automated Swiss Screw Machining fabricates small parts in large quantities and usually out of a variety of metal and plastic materials.

What Are Some of the Market Applications of CNC Machining?

| Industries | Applications |

| Aerospace & Defense | From landing gear to engine components, aircrafts are composed of assembled complex machined products to enable their functionality. Products made for commercial or government aircrafts must comply with industry specifications, hold tight tolerances, and be of the highest-quality. |

| Maritime | Underwater vessels require high precision components to ensure the integrity of the body when it is partially or fully submerged in water. |

| Green Energy | Different green energy technologies and components must be created with durable material to corrosion and weathering. Wind and water turbines require complex and accurate component to efficiently convert natural resources into clean energy. |

| Medical | From the metal components in CT and MRI machines to dental instruments, medical technology and tools incorporate detailed and varying sized machined components. These parts must be manufactured with precision and high-quality, and created from a wide range of materials. |